How Network APIs Are Driving the Next Industrial Revolution in Manufacturing

According to a recent report by GSMA, network APIs are revolutionizing the manufacturing industry by enabling real-time data exchange, automation, and secure integration. These technologies empower manufacturers to optimize efficiency, enhance operational resilience, and boost innovation across their supply chains as the sector embraces Industry 4.0.

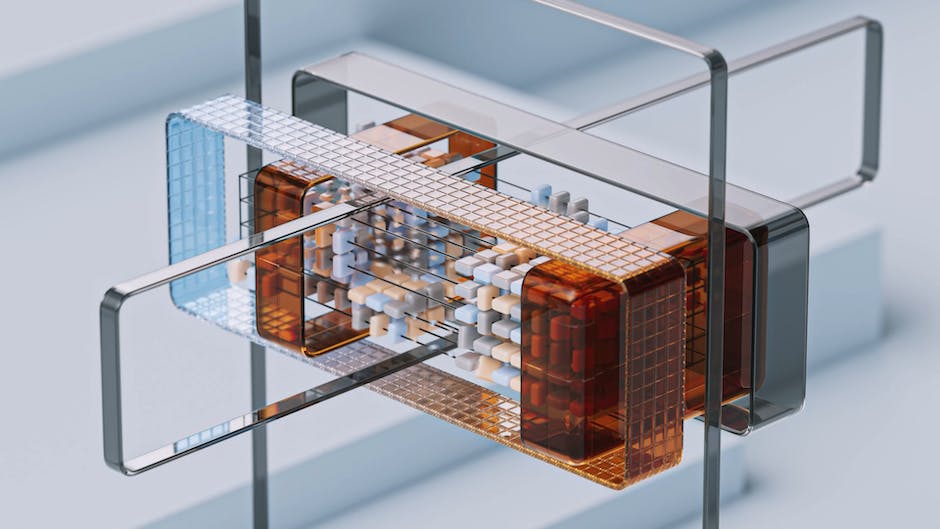

Network APIs: The Core of Smarter Manufacturing

The GSMA’s latest whitepaper, titled Network APIs for Manufacturing: From Technical Potential to Enterprise Impact, dives into how programmable networks are reshaping the industrial landscape. Unlike traditional connectivity, network APIs allow manufacturers to dynamically interact with network capabilities such as provisioning, service orchestration, and performance optimization. Key use cases include:

- Application Credential Management: Enhancing system security and credential integrity.

- Asset Tracking: Real-time monitoring of high-value tools and inventory.

- Quality on Demand (QoD): Reducing production defects through precise process control.

- Network Resource Booking: Allocating network slices for critical operations or applications.

For instance, Airbus leverages APIs such as Location APIs to track and manage smart tools across their aircraft assembly lines, ensuring traceability and reducing operational inefficiencies. Similarly, Portuguese cement manufacturer CIMPOR demonstrates the value of private 5G networks paired with APIs, enabling low-latency, real-time monitoring for anomaly detection and drone inspections of their facilities.

Industry Implications: Why This Matters Now

As global manufacturers face mounting pressures like rising costs, supply chain disruptions, and demands for greater customization, APIs are becoming an essential tool for driving competitive advantage. Industry 4.0 initiatives hinge on the adoption of cutting-edge technologies like AI, IoT, and robotics, with APIs acting as the critical connective layer that integrates these solutions seamlessly across operations.

Market data underscores the urgency of this shift. A recent McKinsey study highlights that by 2030, Industry 4.0 solutions could generate over $3.7 trillion in productivity improvements worldwide. Network APIs are central to realizing this potential, allowing companies to:

- Boost productivity through automation.

- Enhance resilience by responding dynamically to operational disruptions.

- Achieve cost efficiency by optimizing resource allocation.

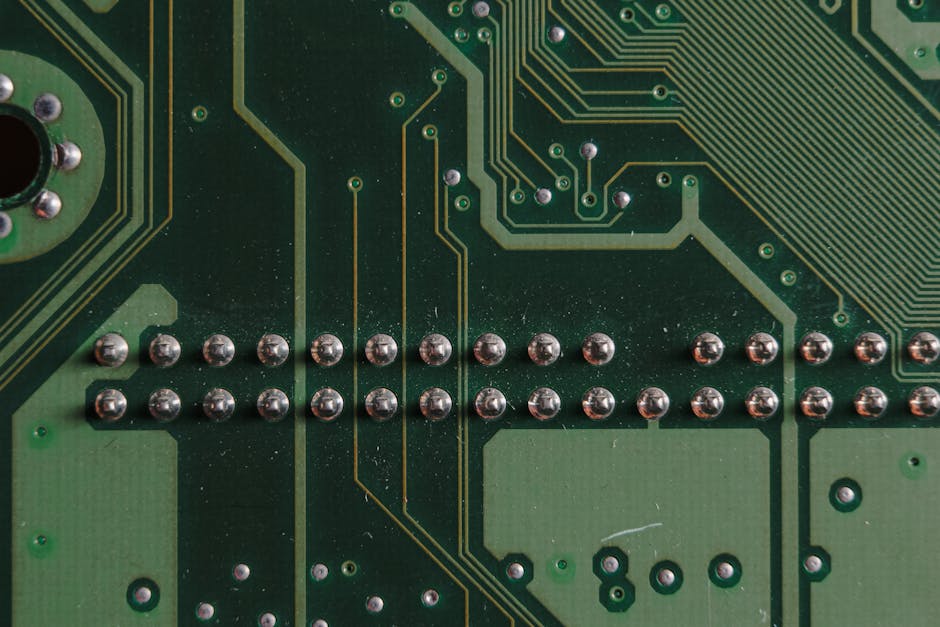

Furthermore, 68% of manufacturers now rank cybersecurity as their top digital transformation priority, according to GSMA’s report. APIs with programmable safeguards are crucial in protecting against escalating cyber threats, as these systems can detect and mitigate intrusions in real-time—far more effectively than static, legacy infrastructure.

The Path Forward: Expert Analysis and Market Vision

Moving from proof-of-concept to scalable adoption of network APIs requires cross-industry collaboration. Initiatives such as GSMA Open Gateway and CAMARA are already addressing this by standardizing access to network capabilities. This “network-as-code” model makes it easier for enterprises and developers—regardless of telecom expertise—to implement innovative solutions quickly and cost-effectively.

For example, IBM and Ericsson are major proponents of integrating API-driven services with AI-powered analytics to optimize manufacturing operations. Experts project that with clearer ROI metrics—such as reduced downtime, improved quality assurance, and the creation of new revenue streams—API adoption will accelerate. As more early adopters like Airbus and CIMPOR showcase tangible gains, the momentum behind APIs as a foundational Industry 4.0 technology is expected to solidify further.

However, challenges remain, including interoperability between different API solutions and aligning application development with proprietary telecom requirements. Overcoming these barriers will be key to unlocking APIs’ full market potential.

What’s Next for Manufacturers?

The advent of network APIs signals a pivotal shift for manufacturing, transforming the sector from a connectivity-dependent model to one where programmable, data-rich networks redefine productivity and innovation. To stay competitive, manufacturers must prioritize API adoption while collaborating with telecom providers, IoT vendors, and technology leaders to build flexible, scalable ecosystems.

Are network APIs the missing link for Industry 4.0 success? Share your thoughts below or join the conversation at the upcoming GSMA Connected Manufacturing and Production Forum.